Understanding Bathroom Vanity Plumbing Rough-In: Bathroom Vanity Plumbing Rough In

The bathroom vanity plumbing rough-in is a crucial stage in the construction process, laying the foundation for a functional and aesthetically pleasing bathroom. It involves installing the necessary pipes and fixtures to connect the vanity to the water supply and drainage system. This step is essential for ensuring a smooth and efficient plumbing system.

Key Components of a Bathroom Vanity Plumbing Rough-In, Bathroom vanity plumbing rough in

The bathroom vanity plumbing rough-in involves several essential components that work together to ensure proper water supply and drainage. These components include:

- Supply Lines: These are the pipes that deliver water to the vanity’s faucets. They are typically made of copper or PEX (cross-linked polyethylene) and connect to the main water supply line.

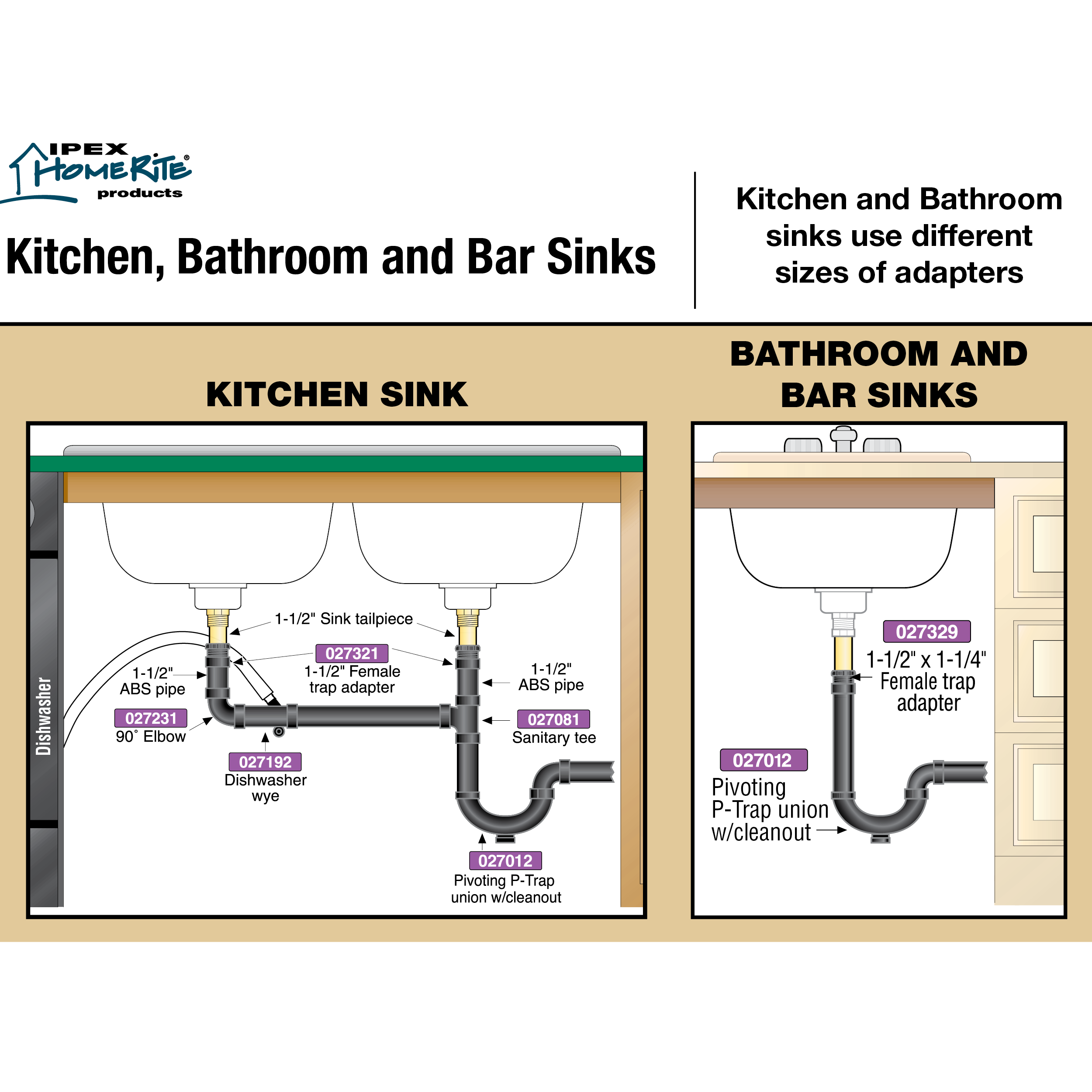

- Drain Lines: These are the pipes that carry wastewater away from the vanity’s sink and drain. They are usually made of PVC (polyvinyl chloride) or ABS (acrylonitrile butadine styrene) and connect to the main drainage system.

- Vent Pipes: These pipes allow air to enter the drainage system, preventing suction and ensuring proper water flow. They are typically made of PVC or ABS and connect to the main vent system.

Standard Dimensions and Placement Guidelines

To ensure proper functionality and aesthetic appeal, bathroom vanity plumbing rough-ins adhere to specific dimensions and placement guidelines. These guidelines vary depending on local building codes and regulations, but common standards include:

- Supply Line Placement: Supply lines are typically placed 16 inches from the finished wall, allowing for easy access to the vanity’s faucets.

- Drain Line Placement: Drain lines are usually positioned 18 inches from the finished wall, with a minimum of 2 inches of clearance between the drain pipe and the wall.

- Vent Pipe Placement: Vent pipes are typically placed above the drain line and should be vented to the exterior of the building.

“The placement of bathroom vanity plumbing rough-ins should be carefully considered to ensure proper drainage and water flow, while also allowing for sufficient clearance for the vanity and its fixtures.”

Common Considerations for Bathroom Vanity Plumbing Rough-Ins

When planning a bathroom vanity plumbing rough-in, several important considerations should be taken into account:

- Access for Maintenance: The plumbing should be installed in a way that allows for easy access for maintenance and repairs.

- Vanity Size and Style: The plumbing rough-in should be compatible with the size and style of the chosen vanity.

- Water Pressure: The water pressure should be adequate to support the chosen faucets and fixtures.

- Drainage Capacity: The drainage system should have sufficient capacity to handle the anticipated water flow from the vanity.

Bathroom Vanity Plumbing Rough-In Installation Process

The bathroom vanity plumbing rough-in installation is a crucial step in the construction or renovation process. It involves setting up the pipes and fixtures that will supply water to your vanity and drain wastewater away. This process requires careful planning and execution to ensure a functional and leak-proof system.

Materials and Tools Needed

Before you begin, you’ll need to gather the necessary materials and tools for a successful bathroom vanity plumbing rough-in installation. These include:

- Pipes: Copper, PEX, or PVC pipes are commonly used for bathroom vanity plumbing. The choice depends on local codes and personal preferences.

- Fittings: Elbows, tees, couplings, and unions are needed to connect the pipes and create the desired layout.

- Drain: A P-trap, a drain pipe, and a vent pipe are essential for proper drainage and odor prevention.

- Shut-off valves: Install shut-off valves for both hot and cold water lines to allow for easy access and control.

- Tools: You’ll need basic plumbing tools such as pipe cutters, a hacksaw, a pipe wrench, a channel-lock pliers, a level, and a tape measure.

Installation Process

The installation process involves several steps:

- Plan the layout: Determine the location of the vanity and the position of the hot and cold water lines and the drain. Consider the distance from the existing water supply and drain lines and any obstacles that might be in the way.

- Mark the wall: Once you have a plan, use a pencil and level to mark the wall where the pipes will be installed. Ensure the marks are accurate and level.

- Cut and install the pipes: Cut the pipes to the desired length using a pipe cutter or hacksaw. Install the pipes according to your plan, using fittings to connect them and create the necessary angles.

- Install the drain: Install the P-trap and drain pipe, connecting them to the existing drain line. Ensure the P-trap is properly sloped to prevent clogs.

- Install the shut-off valves: Install the shut-off valves on the hot and cold water lines, ensuring they are accessible and properly secured.

- Test the system: After installing the pipes, drain, and shut-off valves, test the system for leaks by turning on the water supply and checking for leaks at all connections.

Ensuring Proper Drainage and Ventilation

Proper drainage and ventilation are essential for a functional and odor-free bathroom vanity plumbing system.

- P-trap: The P-trap is a crucial component of the drain system, as it prevents sewer gases from entering the bathroom. Ensure the P-trap is properly installed and sloped to allow for proper drainage.

- Vent pipe: A vent pipe is essential for maintaining air pressure in the drain system, preventing siphoning and ensuring proper drainage. The vent pipe should be connected to the drain system and extend above the roofline.

Using Appropriate Fittings and Connections

Using the right fittings and connections is crucial for a secure and leak-proof system.

- Fittings: Choose fittings that are compatible with the type of pipe you are using and that are designed for the specific application. For example, use compression fittings for copper pipes, push-fit fittings for PEX pipes, and solvent-weld fittings for PVC pipes.

- Connections: Ensure all connections are tight and secure. Use pipe dope or Teflon tape on threaded connections to prevent leaks.